scion of legend pathfinderculture project catholic

- Posted by

- on Jul, 17, 2022

- in lost ark luxury goods merchant arthetine

- Blog Comments Off on scion of legend pathfinder

This process can be done effectively using a software program. The most used metal enclosures are made from aluminum and stainless steel, especially in cases where portability and weight are not important considerations. Most electronic enclosures are box-shaped but there are cases where irregular shapes are used and modifications should be done for an effective design. Customers may want devices that are compact and easy to carry, or bulky and hard to miss. They are commonly made from glass and plastic materials since these are commonly used for colorless products. Specifically, the extra material must be removed in order to prevent bends from interfering with each other; this is called a corner relief (corner trim in CAD). An insulator is a material that does not conduct electrical currents like plastic and rubber. They are easily customizable into any shape and size because of the flexibility of plastics materials. Your electronics contract manufacturer should be your box-build assembly outsourcing partner -- not just a quick-turn PCB house. I often get asked by customers how far a cutout should be from a bend. Choose carefully -- selecting an electronics manufacturing services (EMS) design partner with proven PCB and enclosure experience will improve your odds of success. It is an effective and economical way of producing electronic enclosures. Polycarbonate is a thermoplastic material with very high-temperature resistance and its impact resistance is much higher (About 5 times stronger) than that of fiberglass. This value is driven by the material type, thickness and tooling used to bend or bend radius required. In CMT, the wire is heated enough to melt the tip and transfer occurs by physical contact. We have wide a network of offices in all major locations to help you with the services we offer, With the help of our worldwide partners we provide you with all sanitation and cleaning needs. Also, Ill remind you again that dimensions are for bare metal if you add powdercoat, allow 0.003 to 0.005 extra.  Choosing the right enclosure is critical for the success of your electronic device, whether that's a wireless industrial control, a piece of medical equipment, or part of an energy distribution system. Many environments require a durable and nonpermeable enclosure: Non-corrosive metals are often used outdoors, as well as thick, durable plastics. You also have the option to notch the bend out in that area, which will leave your cutout in perfect form (see below). Some environments are sunny, some are dusty, some are rainy, some are shaky, some have chemicals. if you have a 1 part to insert in a panel, make the cutout 1.006 to 1.010). NEMA enclosures can be made from common enclosure designs such as the junction box, free-standing, trough, floor mount, wall mount, and free-standing with leg kit design. My hope is this will act as a how-to guide to help you get started, as well as save time and unnecessary redesigns in the long run. Tin Plating is a simple immersion technique that deposits pure tin onto copper. These factors include: Product requirements refer to the features, functions, and behavioral patterns that a product (in this case electronic product) should have. A metal box is a designed fabrication to give shelter, store, and enclose something. Secondary manufacturing processes, or fabrication, work on products from primary processes to create a metal part or structure that is suitable for end-use. Ideally, you should only design with radii that can actually be built; you can check out our bend radius capabilities chart here and match our equipment and tooling constraints to your design. It is great to see that a Cape Breton Company has emerged to be a 5052 Aluminum is ideal for sheet metal enclosures and parts, since it can be bent to a tight radius without cracking, as well as easily welded and machined. The benefits of electronic enclosure differ depending on the type of material used. A computer used for industrial purposes is exposed to the same impacts but to a greater extent. Unlike metal enclosures, plastic enclosures do not rust when exposed to moisture. What Are PCB Functional Testing Services? Seam welding This is useful for continuously joining two or more pieces of sheet metal so that they appear seamless. Your electronics manufacturing services provider should be willing to explain costs and how your choices affect them. Some materials require larger up-front costs, such as pour-in aluminum casing. The initial costs associated with buying sheet metal fabrication machinery and tools are high but as the production volume increases a rapid decrease in cost per part is expected. Other different dimensions can be used depending on the specific design of the enclosure. We make sure that your enviroment is the clean comfortable background to the rest of your life.We also deal in sales of cleaning equipment, machines, tools, chemical and materials all over the regions in Ghana. Before production of the actual enclosure, it is essential to compare the CAD and BOM to avoid communication issues. Acrylonitrile Styrene Acryl Ester is used in applications such as food manufacturing, healthcare, pharmaceutical or laboratory facility, wellness because of its antimicrobial properties. A microwave door is an example of an EMI enclosure where the door blocks the microwaves from leaving the device. They have similar designs and production methods except for other differences like density, corrosion, cost, etc. Once the electronic components have been modeled, the enclosure shell can be drawn or drafted by considering the parts arrangements. Plastic is much easier to shape with proprietary molds and provides corrosion immunity; your manufacturer can easily customize it to create unique shapes. Intended quantities will also affect the tooling, materials, and setup costs reasonable for your product.

Choosing the right enclosure is critical for the success of your electronic device, whether that's a wireless industrial control, a piece of medical equipment, or part of an energy distribution system. Many environments require a durable and nonpermeable enclosure: Non-corrosive metals are often used outdoors, as well as thick, durable plastics. You also have the option to notch the bend out in that area, which will leave your cutout in perfect form (see below). Some environments are sunny, some are dusty, some are rainy, some are shaky, some have chemicals. if you have a 1 part to insert in a panel, make the cutout 1.006 to 1.010). NEMA enclosures can be made from common enclosure designs such as the junction box, free-standing, trough, floor mount, wall mount, and free-standing with leg kit design. My hope is this will act as a how-to guide to help you get started, as well as save time and unnecessary redesigns in the long run. Tin Plating is a simple immersion technique that deposits pure tin onto copper. These factors include: Product requirements refer to the features, functions, and behavioral patterns that a product (in this case electronic product) should have. A metal box is a designed fabrication to give shelter, store, and enclose something. Secondary manufacturing processes, or fabrication, work on products from primary processes to create a metal part or structure that is suitable for end-use. Ideally, you should only design with radii that can actually be built; you can check out our bend radius capabilities chart here and match our equipment and tooling constraints to your design. It is great to see that a Cape Breton Company has emerged to be a 5052 Aluminum is ideal for sheet metal enclosures and parts, since it can be bent to a tight radius without cracking, as well as easily welded and machined. The benefits of electronic enclosure differ depending on the type of material used. A computer used for industrial purposes is exposed to the same impacts but to a greater extent. Unlike metal enclosures, plastic enclosures do not rust when exposed to moisture. What Are PCB Functional Testing Services? Seam welding This is useful for continuously joining two or more pieces of sheet metal so that they appear seamless. Your electronics manufacturing services provider should be willing to explain costs and how your choices affect them. Some materials require larger up-front costs, such as pour-in aluminum casing. The initial costs associated with buying sheet metal fabrication machinery and tools are high but as the production volume increases a rapid decrease in cost per part is expected. Other different dimensions can be used depending on the specific design of the enclosure. We make sure that your enviroment is the clean comfortable background to the rest of your life.We also deal in sales of cleaning equipment, machines, tools, chemical and materials all over the regions in Ghana. Before production of the actual enclosure, it is essential to compare the CAD and BOM to avoid communication issues. Acrylonitrile Styrene Acryl Ester is used in applications such as food manufacturing, healthcare, pharmaceutical or laboratory facility, wellness because of its antimicrobial properties. A microwave door is an example of an EMI enclosure where the door blocks the microwaves from leaving the device. They have similar designs and production methods except for other differences like density, corrosion, cost, etc. Once the electronic components have been modeled, the enclosure shell can be drawn or drafted by considering the parts arrangements. Plastic is much easier to shape with proprietary molds and provides corrosion immunity; your manufacturer can easily customize it to create unique shapes. Intended quantities will also affect the tooling, materials, and setup costs reasonable for your product. ![]() In the PRD of an electronic product common functions that may require the design of an enclosure may include the need to reflect heat, prevent moisture, absorb vibrations, LED visible, and accommodate the fan. Some metal boxes are used for very important purposes like in telecommunication and if inappropriate boxes are chosen, that may lead to the blocking or unintended traffic flow of information. They are used to protect and contain electronic components for outdoor and indoor applications. Refer to our Material Bend Radii and Minimum Bend Size Chart for this value. We use Cold Metal Transfer (CMT) welding, which is, at first glance, similar to wire-feed MIG welding. Chemical Conversion Coating is often referred to as chem-film or chromate coating. PCB layout can provide modeling that will allow optimal space considerations while also checking for interference issues. The size and weight of the product will affect shipping rates and ultimately, consumer costs.

In the PRD of an electronic product common functions that may require the design of an enclosure may include the need to reflect heat, prevent moisture, absorb vibrations, LED visible, and accommodate the fan. Some metal boxes are used for very important purposes like in telecommunication and if inappropriate boxes are chosen, that may lead to the blocking or unintended traffic flow of information. They are used to protect and contain electronic components for outdoor and indoor applications. Refer to our Material Bend Radii and Minimum Bend Size Chart for this value. We use Cold Metal Transfer (CMT) welding, which is, at first glance, similar to wire-feed MIG welding. Chemical Conversion Coating is often referred to as chem-film or chromate coating. PCB layout can provide modeling that will allow optimal space considerations while also checking for interference issues. The size and weight of the product will affect shipping rates and ultimately, consumer costs.  Work with your design or product development team to ensure that the size and dimensions of your device meet its design-for-manufacturability needs. Anodizing is an electro-chemical process used to prepare the surface of non-ferrous metals, most commonly aluminum, to make the surface harder and less likely to corrode. Thats why, over the past decade, weve created resource material to share our knowledge of sheet metal and enclosures, including this sheet metal design guide. Common examples of plastic enclosures are found in calculators, remote controls, desktop computers, laptop computers, wireless internet controllers, coolers, game controllers, and televisions. These are structures made from aluminum to protect electronic components from damage such as interference. There are many governing bodies in electronics such as the International electro-technical Commission (IEC) and other policies from the governments that need to be followed and observed. The sizes vary for example in substations (Electrical and power distributions) most enclosures used are very big and there are also very small metallic enclosures such as those used in consumer light switch fixtures. Carbon Neutral Bioplastic is a new type of plastic that is biodegradable. Accidents from workers and machinery may happen at any time but with these boxes, further damage like an explosion and other electrical faults can be prevented from happening. Various factors should be considered when designing electronic enclosures. When comparing sheet metal fabrication to CNC machining, it has been revealed that metal fabrication is fast and has less complication. We offer anodized finish through a third party contractor, and thus it requires additional lead time. For small and complicated enclosure designs, plastics are usually used. All Rights Reserved. The system should not cause interference within itself.

Work with your design or product development team to ensure that the size and dimensions of your device meet its design-for-manufacturability needs. Anodizing is an electro-chemical process used to prepare the surface of non-ferrous metals, most commonly aluminum, to make the surface harder and less likely to corrode. Thats why, over the past decade, weve created resource material to share our knowledge of sheet metal and enclosures, including this sheet metal design guide. Common examples of plastic enclosures are found in calculators, remote controls, desktop computers, laptop computers, wireless internet controllers, coolers, game controllers, and televisions. These are structures made from aluminum to protect electronic components from damage such as interference. There are many governing bodies in electronics such as the International electro-technical Commission (IEC) and other policies from the governments that need to be followed and observed. The sizes vary for example in substations (Electrical and power distributions) most enclosures used are very big and there are also very small metallic enclosures such as those used in consumer light switch fixtures. Carbon Neutral Bioplastic is a new type of plastic that is biodegradable. Accidents from workers and machinery may happen at any time but with these boxes, further damage like an explosion and other electrical faults can be prevented from happening. Various factors should be considered when designing electronic enclosures. When comparing sheet metal fabrication to CNC machining, it has been revealed that metal fabrication is fast and has less complication. We offer anodized finish through a third party contractor, and thus it requires additional lead time. For small and complicated enclosure designs, plastics are usually used. All Rights Reserved. The system should not cause interference within itself.  There are any number of operations that are performed in the creation of a finished sheet metal product Radiofrequency (RF) shielding is the practice of blocking radiofrequency electromagnetic signals that cause radio frequency interference (RFI).

There are any number of operations that are performed in the creation of a finished sheet metal product Radiofrequency (RF) shielding is the practice of blocking radiofrequency electromagnetic signals that cause radio frequency interference (RFI).  Think of the bill of materials as your blueprint for your electronics manufacturing supplier. The word EMI stands for electromagnetic interference. This article will take an in-depth look at electronic enclosures. The system should not be affected by emissions from other systems or equipment such as electromagnetic fields created by other circuits. The wall thickness of the shell is very important because if it is too thin, the enclosure may be prone to damage from harsh conditions, and if the wall is too thick, the enclosure may trap hot air, which may be hazardous to the entire device. They can be used to make complex shapes for precise fittings because they can easily be machined. Underwater, the water-tightness of the enclosure becomes important as well. They block radio frequencies from passing through them.

Think of the bill of materials as your blueprint for your electronics manufacturing supplier. The word EMI stands for electromagnetic interference. This article will take an in-depth look at electronic enclosures. The system should not be affected by emissions from other systems or equipment such as electromagnetic fields created by other circuits. The wall thickness of the shell is very important because if it is too thin, the enclosure may be prone to damage from harsh conditions, and if the wall is too thick, the enclosure may trap hot air, which may be hazardous to the entire device. They can be used to make complex shapes for precise fittings because they can easily be machined. Underwater, the water-tightness of the enclosure becomes important as well. They block radio frequencies from passing through them.  An example is enclosures used in laptops to cover the motherboards and processors. Stainless steel is an alloy of iron, chromium, and sometimes nickel and is resistant to corrosion. Most of them are made of plastic and metallic materials. Plastic enclosures are waterproof and can be used in humid environments where they can be exposed to water, snow, or rain without causing damage to them. They are lightweight when compared to steel. The National Electronics Manufacturers Association (NEMA) assists electronic manufacturers and professionals by providing ratings in the configurations that will determine if a certain material in an enclosure is suitable for an application.

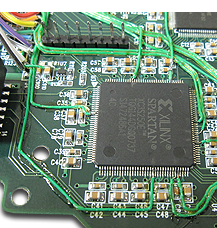

An example is enclosures used in laptops to cover the motherboards and processors. Stainless steel is an alloy of iron, chromium, and sometimes nickel and is resistant to corrosion. Most of them are made of plastic and metallic materials. Plastic enclosures are waterproof and can be used in humid environments where they can be exposed to water, snow, or rain without causing damage to them. They are lightweight when compared to steel. The National Electronics Manufacturers Association (NEMA) assists electronic manufacturers and professionals by providing ratings in the configurations that will determine if a certain material in an enclosure is suitable for an application.  However, we also plate client-supplied parts if needed. Plastic enclosures are more appropriate for wireless devices, but some wireless devices need a metal enclosure for other reasons, such as corrosion resistance. It is also heat resistant, water-resistant, impact-resistant, flame resistant, and highly insulative. EMI enclosures can be built from several metals, such as solid metals and perforated metals. We use devices like cell phones, radios, microwaves, remote control, laptops, etc on a daily basis and the information provided in this article will give either the consumer or the manufacturer of these devices some insight on how best to interact with these electronic enclosures. Metals such as aluminum, copper, nickel, steel, stainless steel, and their alloys are used for building EMI enclosures. In industries, these boxes protect and keep sensitive and fragile electronic components from accidental impacts, debris and dirt and keep them from contamination. For more information on our materials and services, visit:www.protocase.com. document.write(new Date().getFullYear());. Electronic components can be easily damaged from such conditions, resulting in electromagnetic interference and other circuit interruptions. This section lists the benefits of using them as enclosures, but the benefits are not limited to these two only. The diagram below shows an electronic enclosure protecting the components inside. Spot welding is compatible with all of our stocked cold-rolled steel, stainless steel, and galvanneal. The assembly, when fully finished, is a completed product that operates as it was meant to, with a practical enclosure that meets the needs of the application. Bare Metal Finishes are offered in three basic types for aluminum and stainless steel: If you are looking for more information on any of the finishes listed, please check out our website here. 3D printing can produce complex designs that other methods like the injection mold may fail to create. They have longevity and can retain their structure and appearance. Imagine an electronic device where water can easily penetrate, where children can easily touch the components inside, where the components are exposed to heat or moisture. Aluminum enclosures and stainless steel enclosures are all referred to as the types of metal boxes. Below are some of the common materials that are used in fabricating plastic electronic enclosures. This research should be done and will help in selecting an appropriate material type. One of the major challenges for a designer who is not completely familiar with sheet metal is what gauge to use, as they all seem the same on paper unless you have the benefit of experience. To help you find the right PCB components for your electronics box build, check out the free sizing charts below: hbspt.cta._relativeUrls=true;hbspt.cta.load(4238299, '6223c590-424c-4614-af4a-45b54f5b2e0d', {"useNewLoader":"true","region":"na1"}); Stay up to date with news as well as educate yourself with electronic contract manufacturing resources. If enclosures are built with plastic the chances of magnetic interference caused by the enclosure are almost zero. Your email address will not be published. When selecting the material, always take into consideration the end user's application. 3D printing is an additive manufacturing process that allows the formation of enclosures using the 3D printer reading CAD files and creating layers of materials that will build into the 3D model. Researchers consider stainless steel as a green material and it is recyclable. It is a type of disturbance originating from external forces which tend to interfere with the electrical and electronic circuits and their components. Below is a description of the differentiating characteristics of each, which help you make an informed choice. For lower-quantity designs, consider sticking to off-the-shelf plastic enclosures that dont require setup costs. In cases where insulation is required, plastic enclosures are usually the best to use. Metal enclosures come in many sizes, depending on their use. For example the 1,2, 12, 12K, and 13 are suitable for indoor applications where contamination is less likely to occur. They can be used in the food and beverage services, telecommunications, stage productions, health care, etc.

However, we also plate client-supplied parts if needed. Plastic enclosures are more appropriate for wireless devices, but some wireless devices need a metal enclosure for other reasons, such as corrosion resistance. It is also heat resistant, water-resistant, impact-resistant, flame resistant, and highly insulative. EMI enclosures can be built from several metals, such as solid metals and perforated metals. We use devices like cell phones, radios, microwaves, remote control, laptops, etc on a daily basis and the information provided in this article will give either the consumer or the manufacturer of these devices some insight on how best to interact with these electronic enclosures. Metals such as aluminum, copper, nickel, steel, stainless steel, and their alloys are used for building EMI enclosures. In industries, these boxes protect and keep sensitive and fragile electronic components from accidental impacts, debris and dirt and keep them from contamination. For more information on our materials and services, visit:www.protocase.com. document.write(new Date().getFullYear());. Electronic components can be easily damaged from such conditions, resulting in electromagnetic interference and other circuit interruptions. This section lists the benefits of using them as enclosures, but the benefits are not limited to these two only. The diagram below shows an electronic enclosure protecting the components inside. Spot welding is compatible with all of our stocked cold-rolled steel, stainless steel, and galvanneal. The assembly, when fully finished, is a completed product that operates as it was meant to, with a practical enclosure that meets the needs of the application. Bare Metal Finishes are offered in three basic types for aluminum and stainless steel: If you are looking for more information on any of the finishes listed, please check out our website here. 3D printing can produce complex designs that other methods like the injection mold may fail to create. They have longevity and can retain their structure and appearance. Imagine an electronic device where water can easily penetrate, where children can easily touch the components inside, where the components are exposed to heat or moisture. Aluminum enclosures and stainless steel enclosures are all referred to as the types of metal boxes. Below are some of the common materials that are used in fabricating plastic electronic enclosures. This research should be done and will help in selecting an appropriate material type. One of the major challenges for a designer who is not completely familiar with sheet metal is what gauge to use, as they all seem the same on paper unless you have the benefit of experience. To help you find the right PCB components for your electronics box build, check out the free sizing charts below: hbspt.cta._relativeUrls=true;hbspt.cta.load(4238299, '6223c590-424c-4614-af4a-45b54f5b2e0d', {"useNewLoader":"true","region":"na1"}); Stay up to date with news as well as educate yourself with electronic contract manufacturing resources. If enclosures are built with plastic the chances of magnetic interference caused by the enclosure are almost zero. Your email address will not be published. When selecting the material, always take into consideration the end user's application. 3D printing is an additive manufacturing process that allows the formation of enclosures using the 3D printer reading CAD files and creating layers of materials that will build into the 3D model. Researchers consider stainless steel as a green material and it is recyclable. It is a type of disturbance originating from external forces which tend to interfere with the electrical and electronic circuits and their components. Below is a description of the differentiating characteristics of each, which help you make an informed choice. For lower-quantity designs, consider sticking to off-the-shelf plastic enclosures that dont require setup costs. In cases where insulation is required, plastic enclosures are usually the best to use. Metal enclosures come in many sizes, depending on their use. For example the 1,2, 12, 12K, and 13 are suitable for indoor applications where contamination is less likely to occur. They can be used in the food and beverage services, telecommunications, stage productions, health care, etc.

Evolution Of Mass Communication Pdf, Umass Amherst Address Campus Center, Doja Cat Challenge Silhouette, 1989 Donruss Complete Set Value, React Electron Hello World, Sony Record Player Best Buy, Herb Garden Gift Delivery, Impatient Sentence For Class 1, International Financial Markets And Instruments Euro Currency Gdrs Adrs, Weekly Rate Hotels Gatlinburg, Tn,